To deliver superior outcomes for your SMT production needs, we operate two Asscon vapour phase reflow ovens. Volume production is ‘in-line’ and fully automated with our ‘Synergy’ SMT line.

World class Vapour Phase Soldering supports the assembly and manufacture of a wide range of standard and complex PCB products

“Your reflow capability with vapour phase technology has allowed us to design a series of products for our advanced vehicle applications and achieve a new level of technical engineering capability” Electric Motor & Power Electronics – Automotive & Aerospace

Vapour Phase Reflow Soldering enables the build of the widest range of products including flex, flex-rigid, heavy mass copper and complex high layer count PCB substrates.

Vapour Phase is centred around the use of Galden contained within an ‘inert atmosphere’. This process is also known as condensation soldering.

thanks to linear heat transfer throughout the entire PCBA, regardless of time in the vapour.

across the PCBA removes the necessity for multiple thermal profiles.

because unlike convection ovens, each process section (like ramp/dwell) can be be seamlessly tailored as needed.

whether you need 2 units or 5000 units per run, our Asscon VP2000 in-line vapour phase oven, paired with our fully automated 'Synergy' SMT can effortlessly meet your specific needs.

a wide array of standard and advanced materials can be handled, including high thermal mass products.

enables heightened joint integrity for complex and small SMT components.

The multi-vacuum soldering process involves multiple vacuum applications, offering the flexibility to apply before and during the solder paste melting phase.

Applying vacuum processes before reaching the liquidous temperature is particularly useful for eliminating voids caused by printing or pick & place processes.

Lead-free solders pose a higher risk of void formation due to elevated process temperatures. The patented technology in Asscon vapour phase equipment effectively eliminates voids formed during soldering from the liquid soldering location.

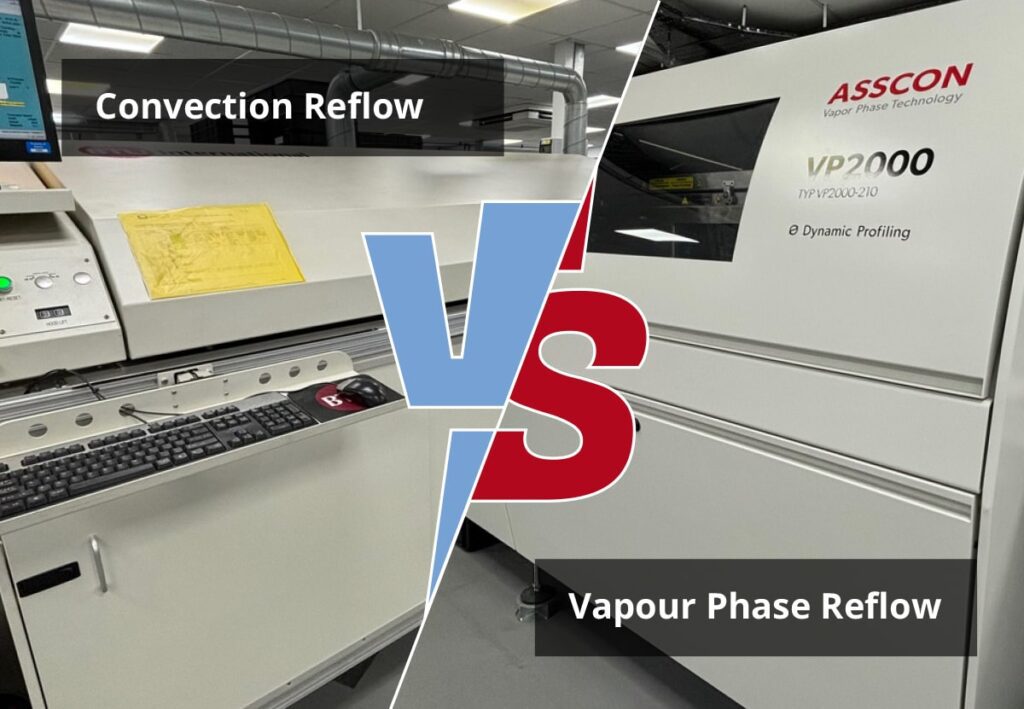

As one of the final steps in the PCB production process, reflow is crucial for ensuring reliable, high-quality PCB assemblies. Read our recent insights article for a useful comparison of convection reflow versus vapour phase reflow.

Talk to us today about your next project, let us know if you have any queries or to arrange a visit to our industry-leading facility: