Gemini Tec are fully committed to significant capital investment in world class production capability and have invested in Nitrogen reflow soldering for 2021. This latest investment increases capacity and capability for HDI and ultra complex PCBA production. And with demand increasing for our CEM services, we’re delighted to increase support for our customers, including those working within the automotive and aerospace sectors.

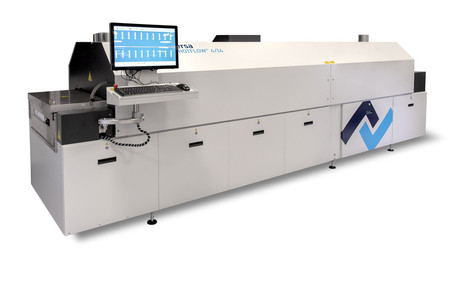

Investment in the latest ERSA Hotflow 4/14 reflow oven from ERSA in Germany will deliver the latest capability to our flagship ‘Trilogy’ surface mount line, allowing for increased production volumes of complex SMT products, where high reliability is a pre-requisite.

As HDI products increase in track and component density the addition of Nitrogen (N2) into the reflow process delivers a higher level of joint integrity. This is achieved by injecting N2 into the reflow chambers during the process, to remove the oxygen and prevent the oxidisation of components during the ramp up phase.

The nitrogen atmosphere improves the wetting of all solder joints, removes the risk of generating solder balls and avoids technical issues such as voiding and HIP (head in pillow) under dense PCBAs using arrays of BGA devices.

Specific highlights of the ERSA Hotflow oven allow vastly improved performance and efficiency. The chosen reflow oven has a low thermal mass in operation and granular level zone control, using advanced on board thermal management software. The ERSA Hotflow is the ideal partner to support higher production throughput using 9 zones (7 heating/2 cooling) and provide full support for complex PCBAs, high thermal mass PCBA’S and thin core substrates for flex and flex-rigid products.

Customers will be updated in due course as we integrate nitrogen reflow and expand our SMT capacity across 2021.

Gemini Tec support a wide range of applications from NPI to medium volume production. Our investment in advanced processing technology allows us to build complex and demanding PCBA products where reliability and quality conformance is mandatory.

If you would like to register your interest in working with us, please get in touch with our commercial team.

Contact us to talk about your requirements in more detail. +44 (0) 1252 333 444

Customer feedback on the service we provide:

“Sangoma recognizes the high levels of quality and professionalism delivered during the development of our next generation of our products. The quality delivered and the turnaround times were a key element in our products. Sangoma is proud to have you as one of its trusted partners for electronic manufacturing services.”