Intelligent Material Costing

In a market where intelligence is critical, we must provide accurate information and data to guide and advise our customers to achieve their strategic objectives.

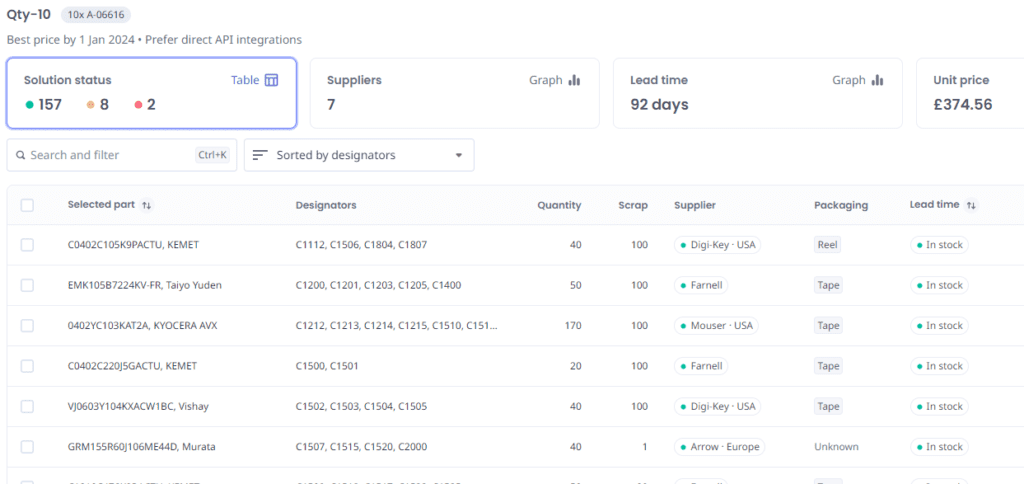

Material lead times

Whether we are working on a demanding NPI program or during the production phase, understanding the material lead time is core to meeting your delivery.

How do we do this at Gemini Tec?

Using clever digital integration, we can map your BOM directly into our supplier’s database to view the actual stock and exact cost in real time.

Is the BOM fully available?

Before creating a quotation for you, we can fully understand and share a picture of the entire BOM.

We can provide valuable insight into all component lead times and potential project blockers. All of this work can be provided in advance of the PCB design, to avoid delays and constraints long before manufacturing commences.

API keys allow us to access our suppliers’ lead time and expected due date. Should a solution not fit the required build program for your product, we can easily search the broader market and understand which suppliers are holding stock and what impact that may have, such as cost implications or supplier risk.

We can also access stock held within our own MRP environment to further reduce lead times.

Limitless Scenario Planning

Crunching data at the touch of a button allows us to create a ‘view’ using any likely scenario. We can now prioritise the lead time over cost to meet the required deadline or project budget.

In the case of resistors and capacitors, our system can work as a co-pilot, offering suitable alternatives based on the exact electrical parameters and once again providing the most suitable solution to meet the lead time.

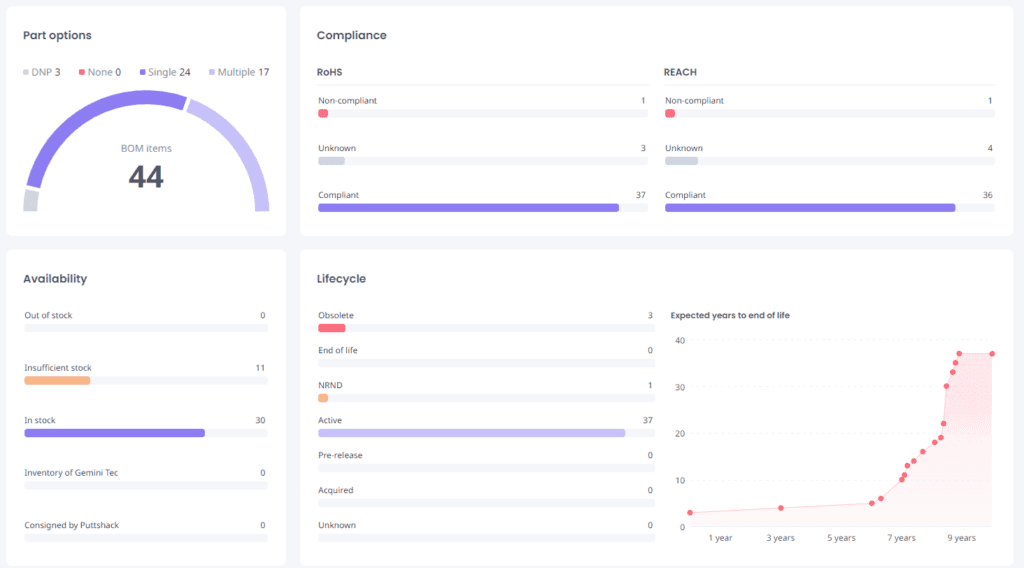

Risk & Compliance

Additional features of our material costing process include a complete overview of all risks within the supply chain and compliance on issues such as RoHS.

Awareness of issues such as component lifecycle will help reduce risk and allow production planning to be managed correctly.

How can you benefit from our capability?

Early engagement with our team is essential in helping you build a solid foundation for the product being designed.

Reviewing the BOM before the PCB design is committed allows a full review of the component availability. At this stage, we can work to remove components that add risk, selecting alternative components to meet the product lifecycle requirements.

Upfront scenario planning will allow informed decisions at key stages to ensure the prototype and production process can be executed correctly.

The electronic component market moves quickly, and part of our role as a strategic partner is to provide advice, guidance and recommendations to allow you to meet your objectives.

Contact us to arrange a briefing where we can understand your requirements in more detail and understand if there is a mutual fit between our companies and how best to partner with us for your CEM needs.